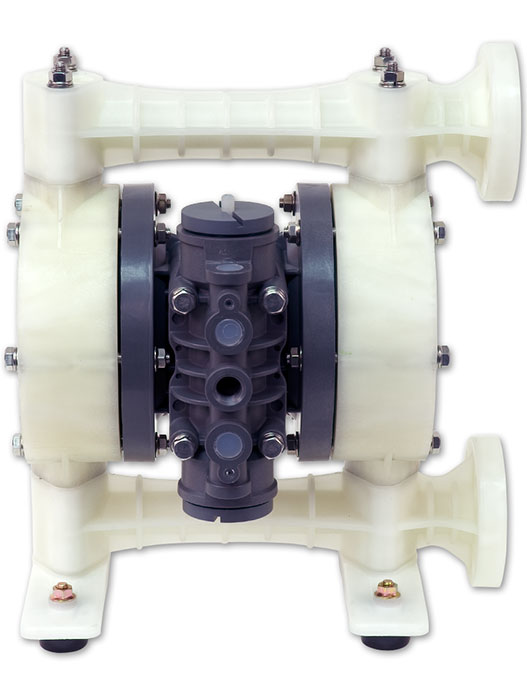

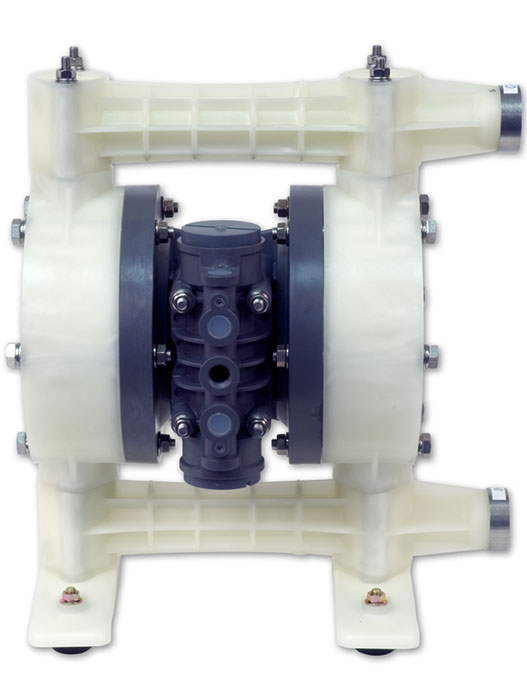

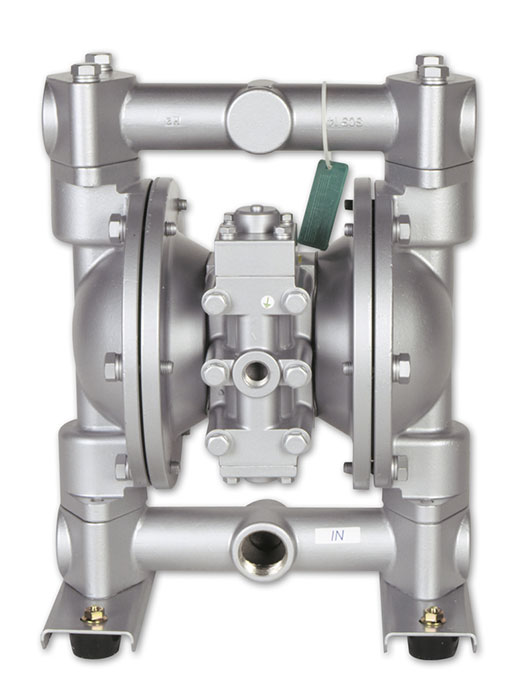

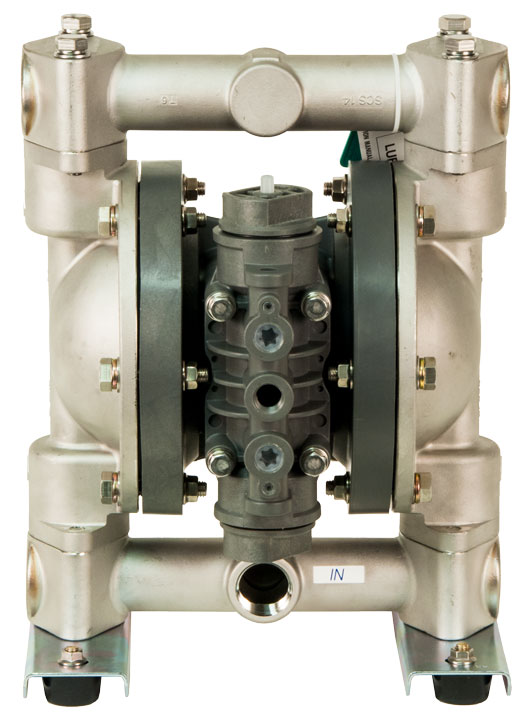

YAMADA Yamada® NDP-25 Series Double Diaphragm Pump

페이지 정보

작성자건아테크 댓글 0건 조회 3,595회 작성일 18-10-16 15:04본문

Yamada® NDP-25 series Air Powered Double Diaphragm (AODD) pumps provide a maximum flow rate of 49 gallons per minute. Pumps are available in aluminum, stainless steel (316), Kynar® (PVDF), groundable acetal, and polypropylene construction.

Unified Air Valve Concept – 2 common size air valve assemblies used for 6 sizes of pumps reducing reassembly confusion and parts inventory

Truly No-Lubricated Air Valve – patented air valve on all NDP series pumps never requires lubrication or pre-packing

Non-Stalling – patented non-centering, 304SS spring-assisted shifter, ensuring a positive shift every time

Tested to last over 300 million cycles

Aides in long dead head application for reliable startup

What separates Yamada from the rest of the pack is our air valve technology. Yamada uses a completely non-lubricated main air valve and independent pilot mechanisms to control the air logic.

As compressed air enters the pump, it is directed via the main air valve to one side or the other, depending upon the starting position of the c-spool. As the air enters the chamber, it forces the diaphragm outward. This outward momentum forces liquid out of the discharge ball valve and loads the opposite inlet ball valve. As the diaphragm travels outward, the connected diaphragm on the opposite side is pulling the diaphragm inward.

When it travels a full stroke, it will contact the pilot valve, depressing it and breaking the seal to open an exhaust port.

The open port allows the compressed air to the exhaust from the back side of the air valve. The pressure drop produces a shift of the main air valve. This motion simply repeats on the other side.

Contact Us

Literatures & Drawings

Videos

댓글목록

등록된 댓글이 없습니다.